|

Zhengzhou Zoonyee mining machinery co, ltd

|

Fine Crusher

| Payment Terms: | T/T,L/C,D/A |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

In the "Rock-on-Rock" Crusher, 70%-80% crushing are caused by the mutual hit among the materials. Hence, the wear load of its hammer head and liner

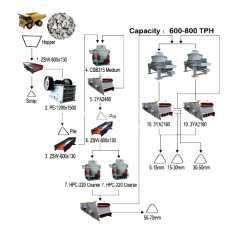

In the "Rock-on-Rock" Crusher, 70%-80% crushing are caused by the mutual hit among the materials. Hence, the wear load of its hammer head and liner are only 20%-30% of the common crusher. The former harmful functions which wear down the hammer head and liner are converted into useful function for material crushing. In this way, the "Rock-on-Rock" cleavage crushing is truly realized. Compared with the common crushers, our PCX high efficiency fine crusher has the advantages of lower consumption, longer service life of wear-resistant parts and higher reduction ratio. It is widely applied in industries, such as sand making, stone crushing, cement, refractory material, metallurgy etc

Feature

Our PCX high efficiency fine crusher has the advantages of lower consumption, longer service life of wear-resistant parts and higher reduction rati

Principle

When raw materials are fed into the fine crusher, they will be hit by the rapidly contrarotating hammer head. The big material will be crushed immediately, and then fly to the impact plate to go through the second collision crushing. The rebounded material will hit with the follow-up flying material and crush each other. After being crushed in the first chamber, crushed material will go through repeated crushing in the second chamber.

Finally, the material will be screened by the discharging grate, qualified product will be discharged from the grate seam, and coarser materials will be returned to the first chamber for repeated crushing. The material layer floats intensively in the crushing chamber. The following fed material rip into the intensive material layer, the rapidly flying materials hit with each other and cleavage crushing happens. The crushed small particles rub and grind with each other and produce plenty of fine powder. Finally, the qualified fine powder will discharge from the grate seam

Parameter

Models | PCX30 | PCX40 | PCX50 | PCX60 | PCX80 | PCX100 | PCX150 | PCX200 | PCX250 |

Feed opening size (mm) | 400×185 | 500×250 | 550×330 | 1000×350 | 1200×400 | 1200×450 | 1500×500 | 1600×550 | 1800×800 |

Feed size (mm) | <120 | <180 | <180 | <180 | <180 | <180 | <190 | <190 | <190 |

Discharge size (mm) | <5 | <5 | <5 | <5 | <5 | <5 | <5 | <5 | <5 |

Discharge adjustment range (mm) | 5-20 | 5-20 | 5-20 | 5-20 | 5-20 | 5-20 | 5-20 | 5-20 | 5-20 |

Cement (T/H) | 20-30 | 35-40 | 35-45 | 45-55 | 80-110 | 100-110 | 100-150 | 170-210 | 250-270 |

Limestone (T/H) | 35-45 | 45-55 | 55-65 | 65-75 | 50-100 | 90-100 | 100-150 | 190-250 | 280-310 |

Power (KW) | 37-45 | 45-55 | 45-55 | 55-75 | 100-110 | 100-132 | 160 | 250 | 315 |